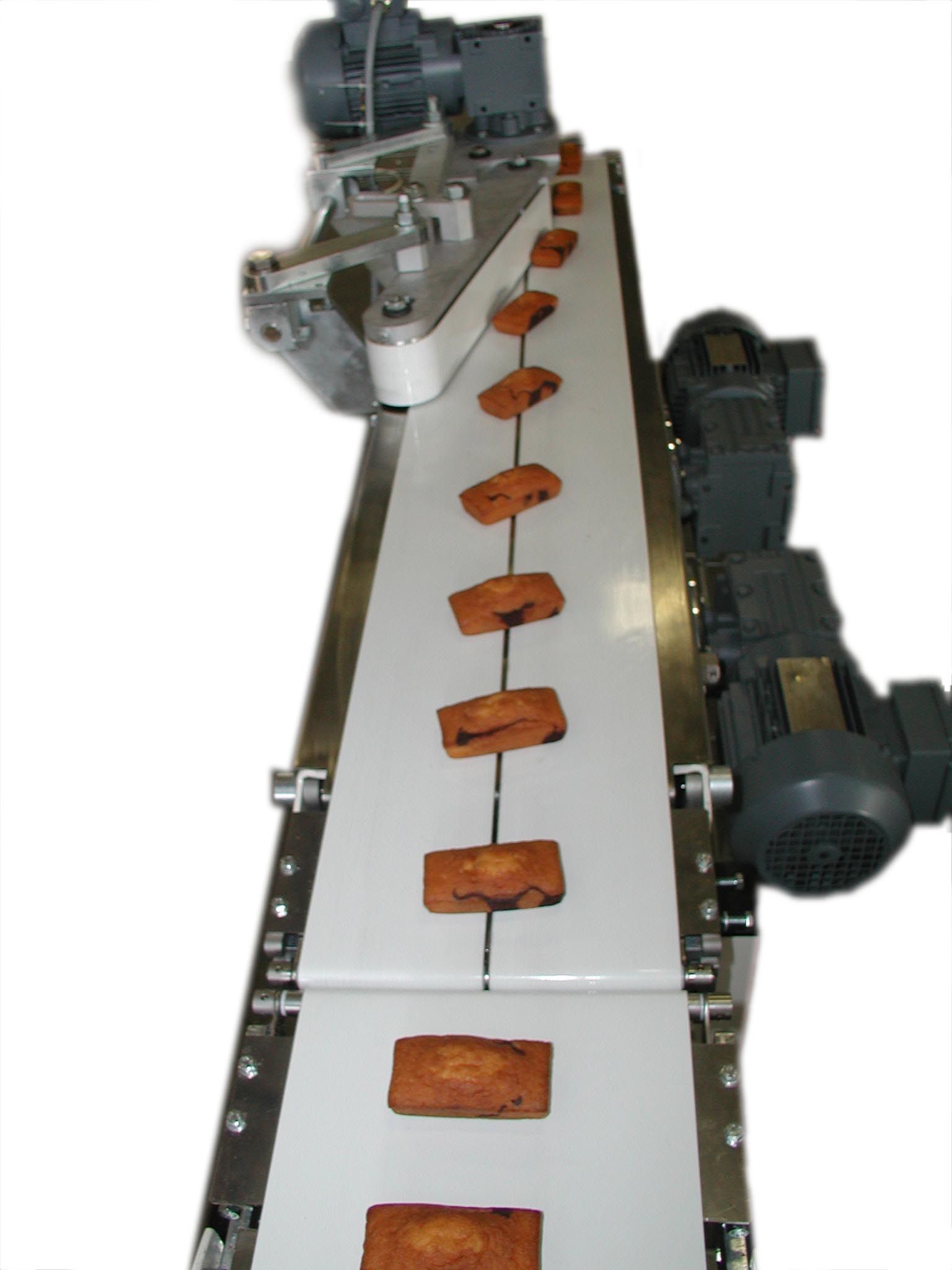

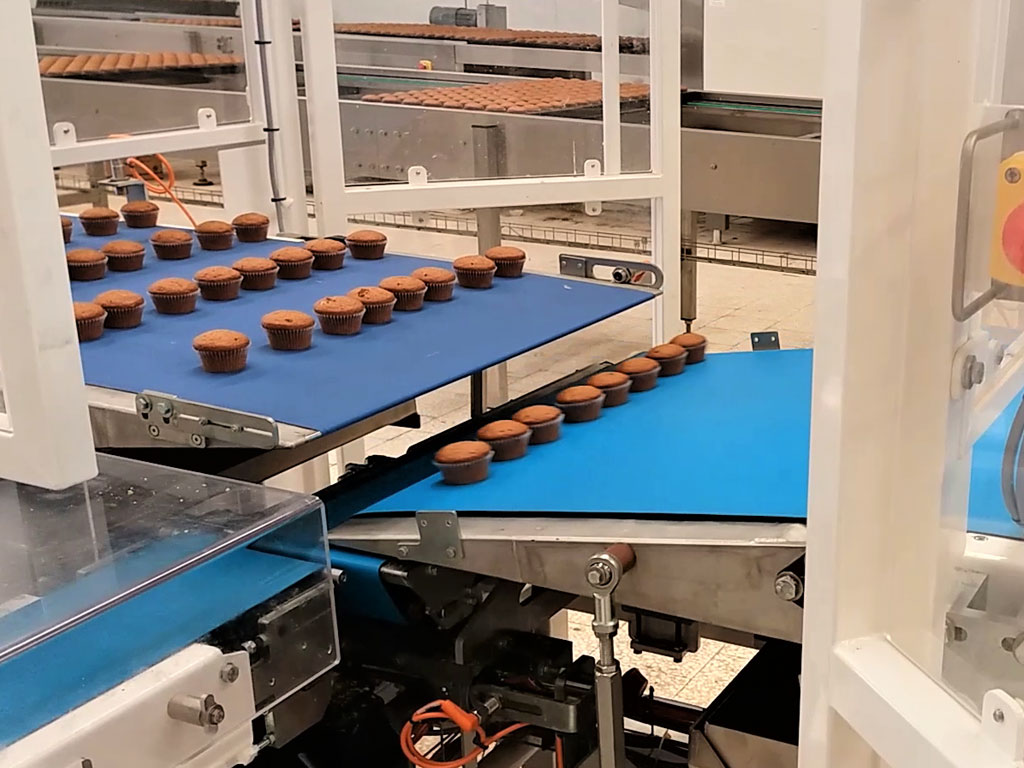

Distribution station

Description

Made up of a 304 L stainless steel structure, with aside mechanic parts, the device ensures easy maintenance and cleaning and quick belt removal. Aiming at spacing out and lining up the products, a couple of conveyors is equipped with an alignment barreer moved by a pneumatic acutator. The lines of products are spaced out following a chosen pace and transfered to the distribution station. At the end of the last in-feed conveyor, the station has a distribution plate which enables to receive a line of product and then deliver it to the out-going conveyor thanks to a mechanic pusher. For easy cleaning and maintenancen the perpenducular conveyor under the station can easily be removed.

Aims

- Handling a flow of products, spacing them out and tranfering them perpendicularly, on one track

- Turning cakes over individually, in the sense of the lenght

- In the case of a stop on the line, a storing conveyor, with an automatic reinsertion sytems can be added.

Technical Information

- Certified CE, UL

- 304 L stainless steel construction

- Pieces in contact with the products are made of stainless steel

- Euro 2 conception

- Automatic belt centring

- Centralized belt tension

Solutions

HANDLING

Products

BISCUITS