Conveyor Whistle

Description

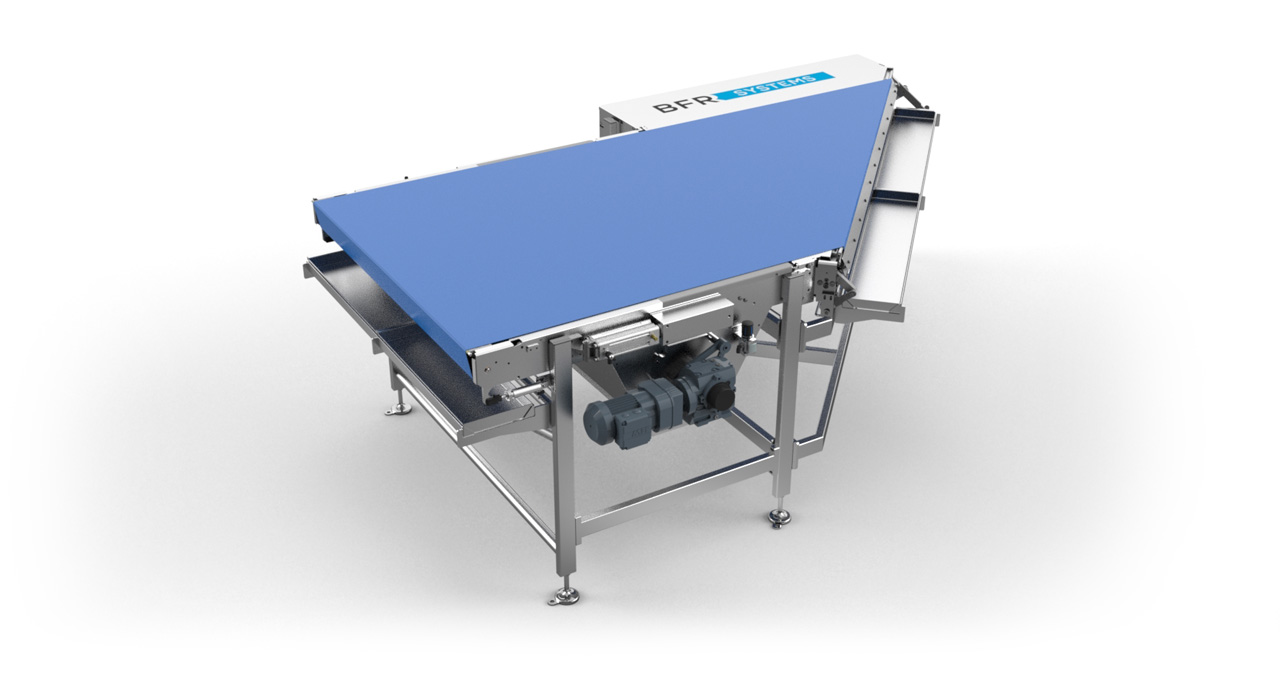

A sprocket-driven belt conveyor is a belt conveyor whose one end has a 45° angle on a fixed blade.

By combining a sprocket-driven belt conveyor with a straight conveyor, a curve or another sprocket-driven belt conveyor, it is possible to orient, separate, tighten, redirect at 90° or align products while minimizing contacts.

BFR sprocket-driven belt conveyors have the same characteristics as straight conveyors:

- Pneumatic belt tension

- Pneumatic belt tracking

- Small diameter ends for small products

- Continuous scraping with waste recovery tray

- Quick belt dismantling possible

- All-stainless steel design without retention zone allowing jet washing if necessary

APPLICATIONS

The applications of whistle conveyors are multiple:

- Widening the flow to facilitate the grip of products by robots, for example

- Narrowing the flow width to feed a tunnel, coater or any other equipment that is narrower than the original flow

- Combining a 90-degree product redirection with a contactless change of orientation

- Bringing back in line products that arrive ordered in rows

Whistle conveyors are commonly used in the biscuit-pastry, viennoiserie, chocolate, and snacking industries, whether in fresh or frozen products.

LEARN MORE

BFR Systems, food packaging machine manufacturers and suppliers of production lines for the food industry. Expertise, innovation, and top-notch customer service.

Contact us today for tailor-made packaging solutions.