Eurocri

EUROCRI WAS FOUNDED IN 1982 AND HAS BEEN PART OF BFR SYSTEMS SINCE 2015

BFR Systems has specialized in specific machinery and will provide you with the best solutions for product handling special machines, automation and robotics projects.

With our patented technologies, we offer you innovation all the way through. Entrust us with your products and we will provide you with the right solution for your project.

Why Eurocri ?

- • The best solutions adapted to your needs.

- • High quality equipment.

- • Innovative solutions.

- • Fast and efficient after-sales service.

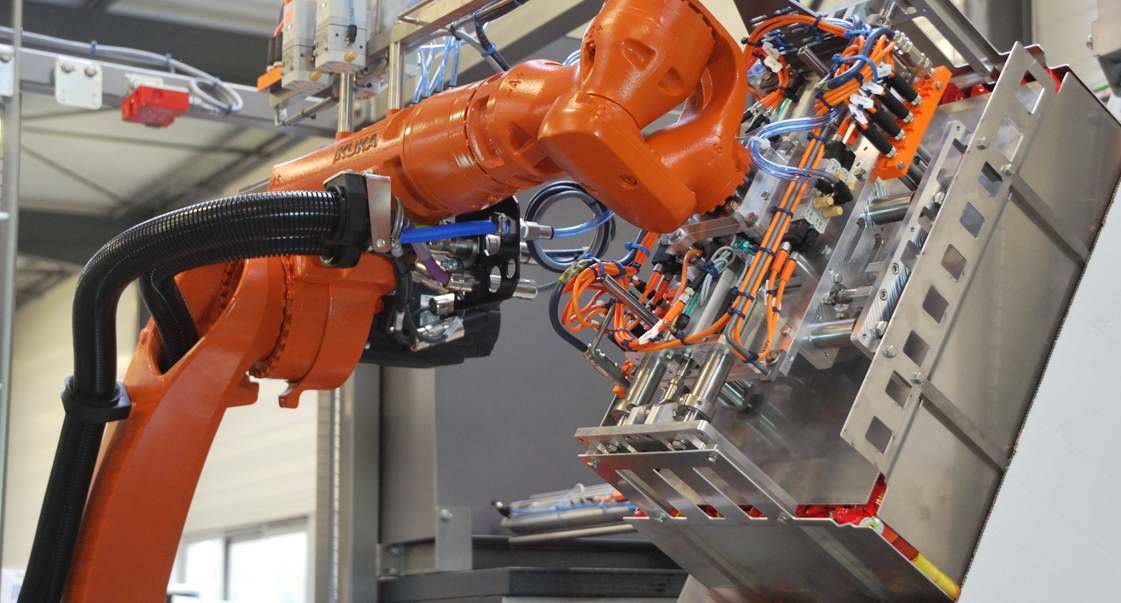

ROBOTICS

BFR Systems has extensive experience in product handling.

- Vision Systems

- Delta or 6-axis robots

- Specific grippers adapted to naked or packaged products.

- High-speed loading of packaging machines or for wet or dry processing operations.

FLOW MANAGEMENT

All types of product conveyors and buffers. Dynamic accumulators and pitching devices, product realignment, grouping and stacking of products.

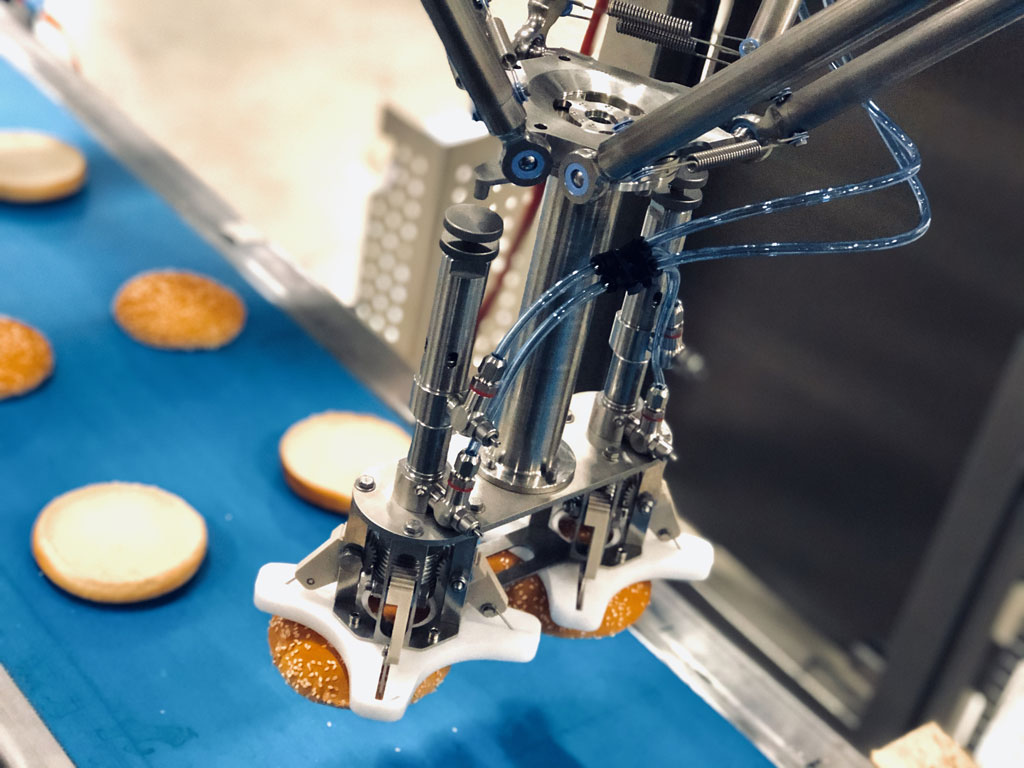

SPECIAL MACHINE

BFR Systems has a significant experience in in slicing and automatic dispensing / dropping products in trays, or in thermoforming machines...

We manufacture custom made machines according to your request.

We pay a special attention to designing machines without retention zones in order to guarantee maximum hygiene.

CLUB SANDWICH LINE

Fully automated unstacking, dosing, closing and slicing machines that are the fastest on the European market.

Their modularity makes them easy to adapt to different productions and they meet all the particularly demanding requirements of the sector.

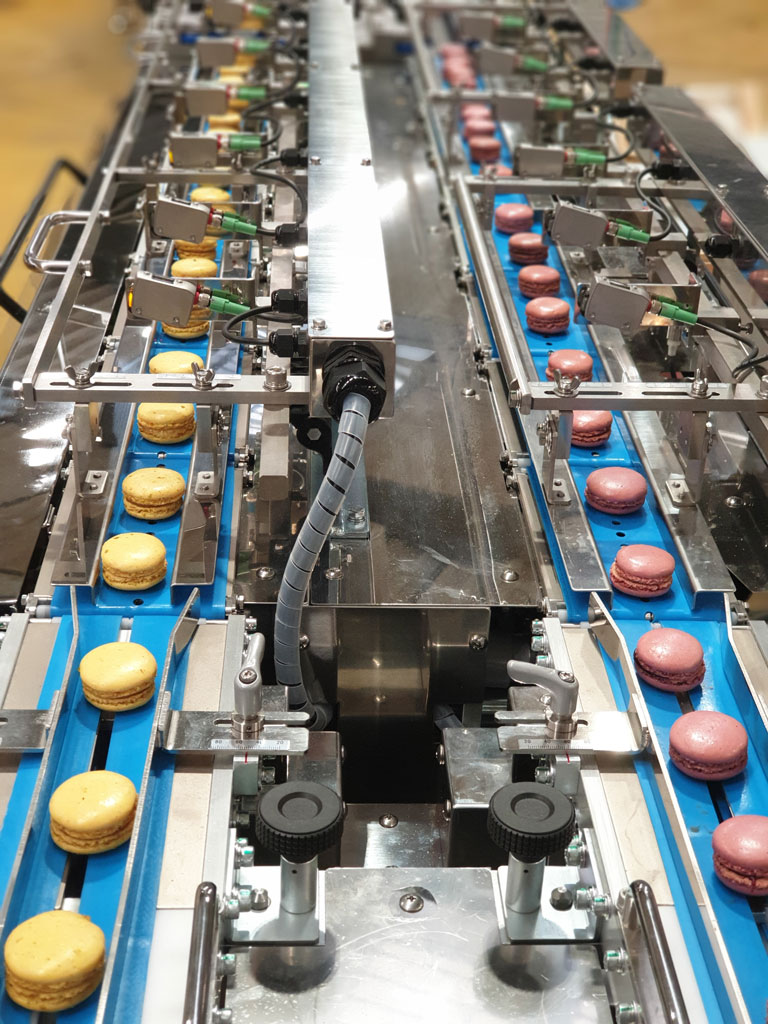

PASTRY LINE

BFR Systems designs and manufactures automatic lines from the oven exit to packing with:

- Cooling conveyors

- Multilevel or U-shaped storage by moving curve

- Row diverger or converger

- Row to flowpack transfer station

- Aligner for products from planar bulk material

- Loading of the flowpack or cartoning by indexing belt or robotic system

- Integration of flowpack (OMORI) and cartoning

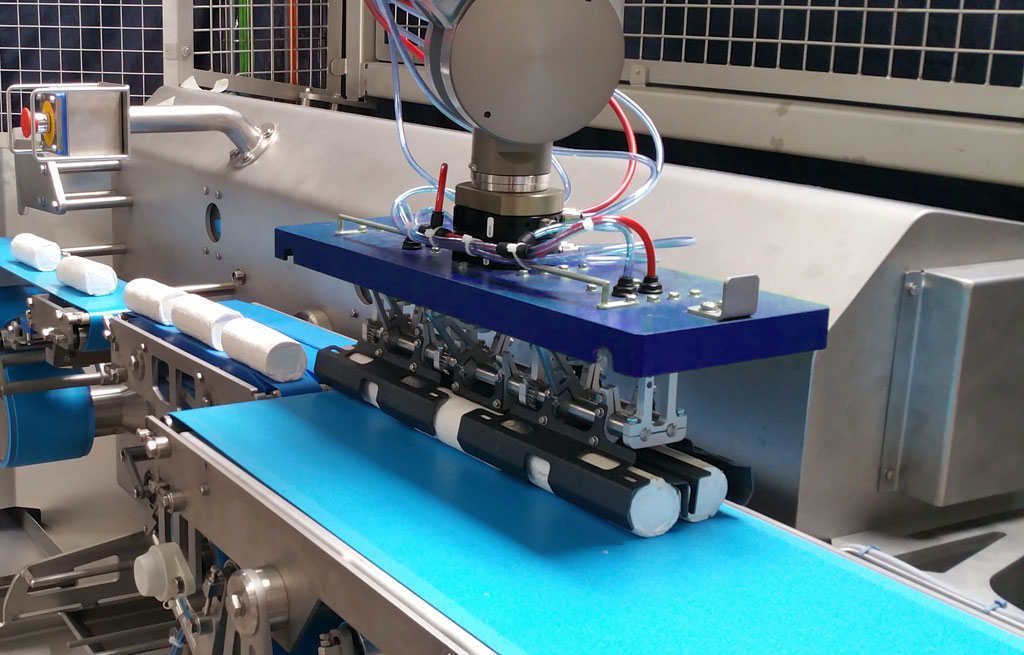

GOAT CHEESE LINE

Automated line for making and packaging fresh cheese.

- Vemag push-button

- Thermoforming loading robot

- CE, UL certification

- Offset mechanics (out of the way of the products) enclosed in a box, with integrated electrical cabinet, guaranteeing high accessibility and therefore easy maintenance and cleaning

- Designed to optimize hygiene with no retention zones or hollow bodies

- Waterproof and pressure-washable frame and structure • Quick removal of the belts