BFR SYSTEMS AND LESSONIA : A SUCCESSFUL COLLABORATION

COSMETICS

PACKAGING

BFR SYSTEMS AND LESSONIA : A SUCCESSFUL COLLABORATION

COSMETICS

PACKAGING

DESIGNER & MANUFACTURER OF COSMETIC PRODUCTS, 100% MADE IN FRANCE

Founded in 2002, LESSONIA is a company specializing in the design and custom manufacturing of cosmetic ingredients and products for brands. Historically focused on algae processing, the company has gradually expanded its activities to include the production and transformation of plant-based materials before shifting to the manufacture and packaging of cosmetic products. Since its founding in 2002, Lessonia has committed to leveraging its expertise while actively contributing to creating a positive impact on the environment.

THE LESSONIA PROJECT

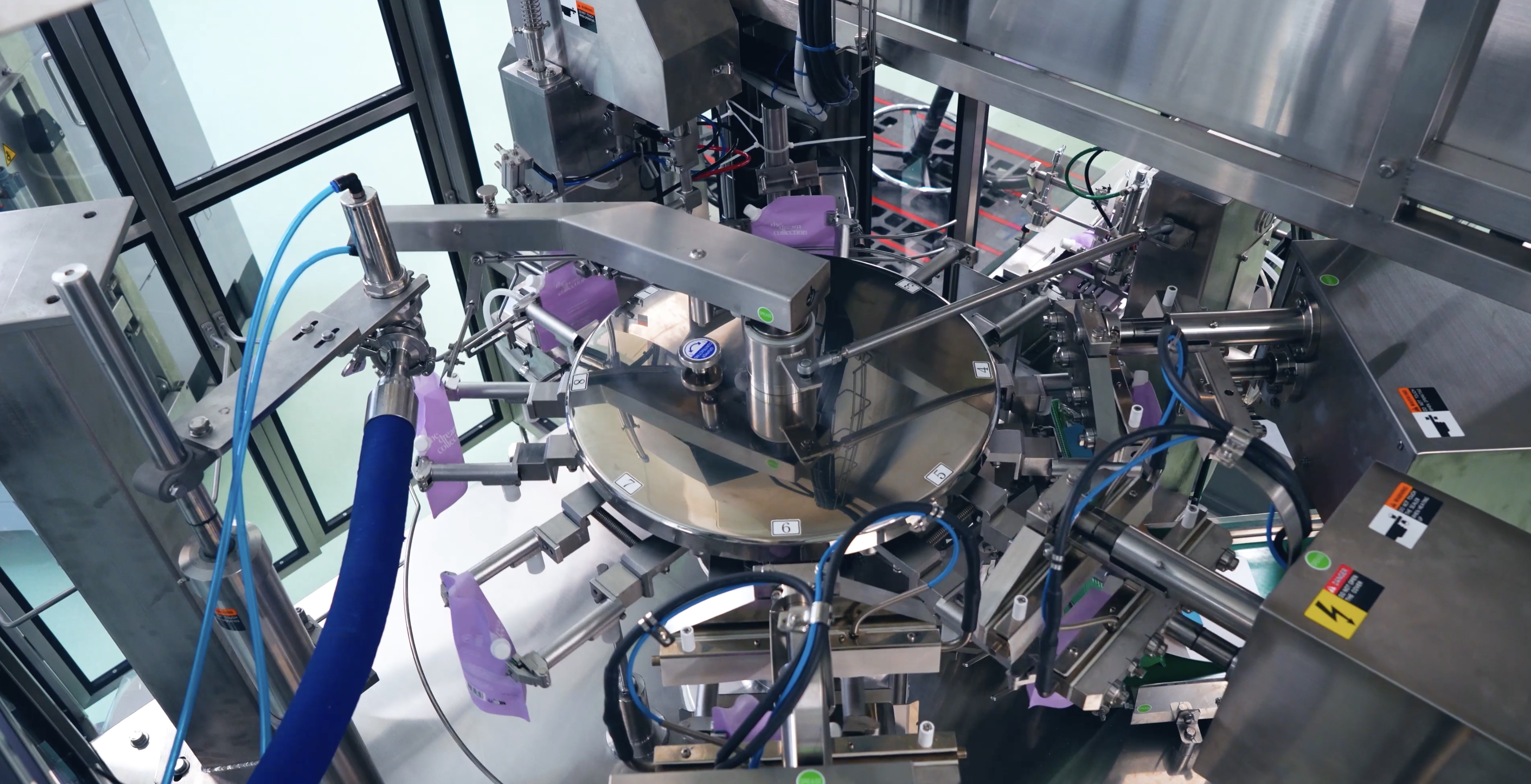

In line with its commitment to the environment, Lessonia wanted to work with 100% recyclable mono-material pouches. Lessonia planned to offer its customers 100% recyclable screw-cap pouches and spouted pouches designed as eco-refills in various formats. The doypack pouch already exists in the hair care industry but is only now entering the skincare market. Lessonia wanted a flexible and adaptable machine for packaging serums, lotions, creams, and scrubs in doypack pouches.

BFR SYSTEMS AND LESSONIA : A SUCCESSFUL COLLABORATION

It was the discovery of our Pacraft bagging machine at BFR Systems' workshops and the observation of its fully mechanical operation that convinced the technical manager of Lessonia. Our bagging machines address all the issues related to mono-material pouches.

PACRAFT, THE DOYPACK PACKAGING SPECIALIST

Pacraft, formerly known as Toyo Jidoki, was founded in 1960 and is now a recognized brand for its expertise in packaging for both the food and cosmetics or pharmaceutical industries. The versatility of its machines allows them to adapt to all customer needs regarding pouch types and sizes, as well as production speeds.

PROVEN RESULTS

Less than a month after its delivery, the machine is operating perfectly with two teams working five days a week, achieving highly satisfactory results according to the Technical Manager. The machine, delivered by BFR Systems, is used intensively and without difficulty, ensuring smooth production for Lessonia.

They trust us

TECHNICAL MANAGER, LESSONIA

"Working with BFR Systems, has been beneficial in several ways : Firstly, the quality of the contacts at BFR Systems, who are not just a 'mailbox' but truly support us and respond to all our questions. The ease of use of the machine allows our teams to manage production without the need to constantly be in contact with the technical team. Lastly, the quick intervention of technicians and the prompt delivery of spare parts enabled a fast and efficient installation of the machine at our site."