Biscuit line, Follower sheets, line reducer and turnaround

Description

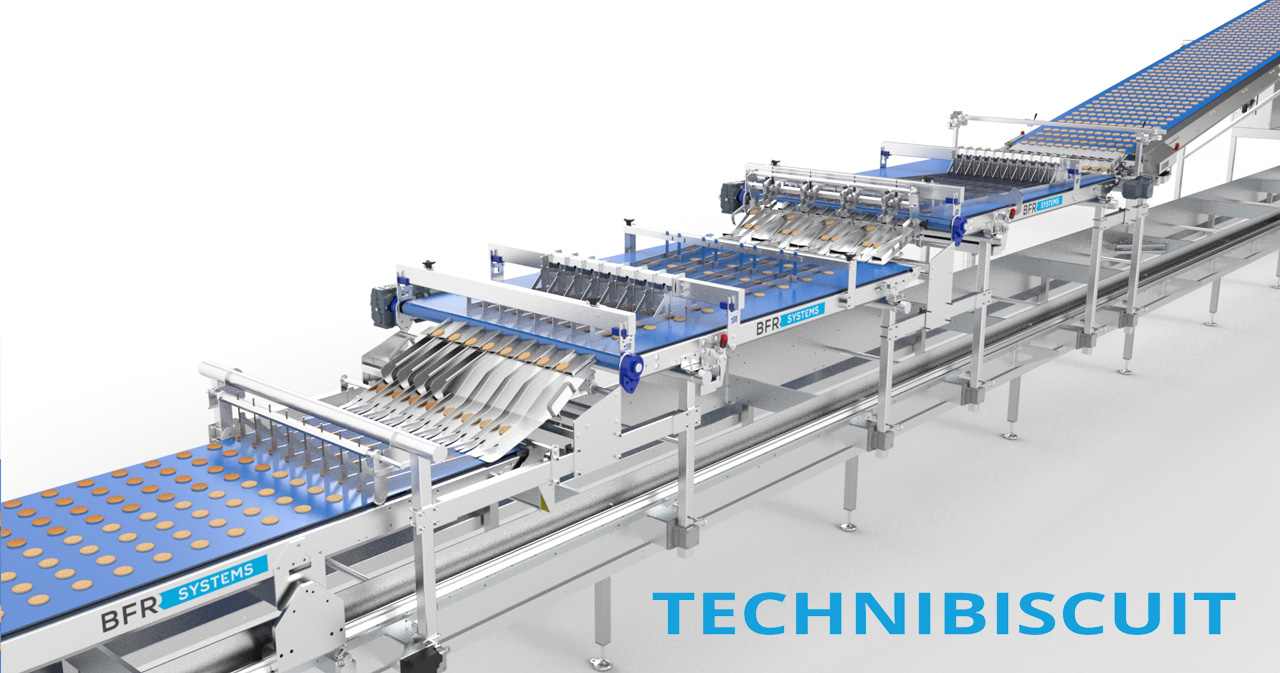

BFR Systems designs and manufactures equipment for handling biscuits as they exit the baking oven.

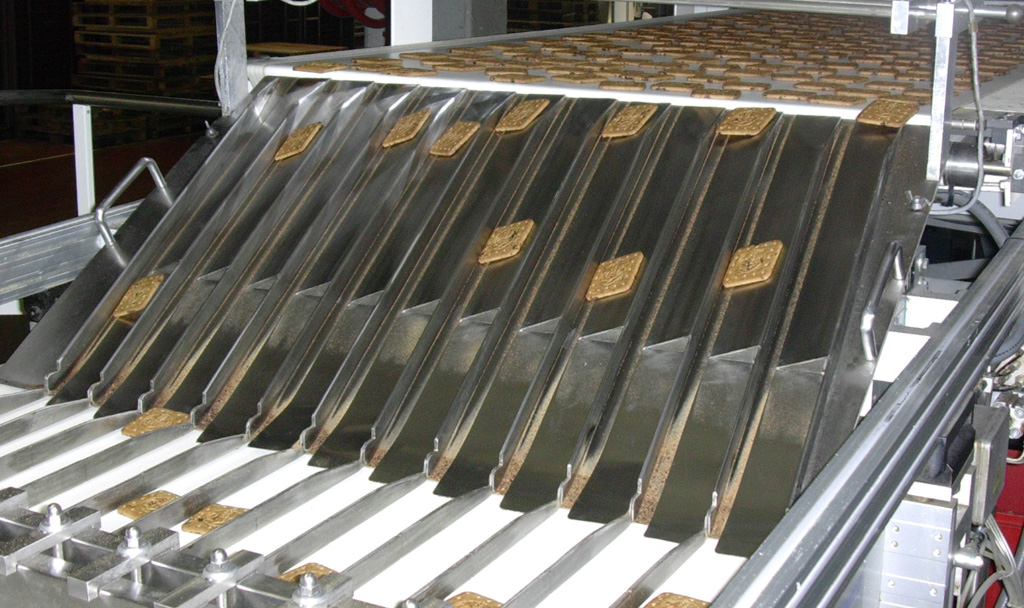

Follower Plate: This equipment, commonly used after cooling conveyors and before packaging, allows for recentering product rows. Thanks to our extensive experience and the variety of products handled, we have acquired recognized expertise.

All our equipment is designed for easy and quick format changes.

Lane Reducer: To adapt the number of rows between the oven's output constraints and the packaging requirements, it is often necessary to incorporate a device for reducing or multiplying rows. Our systems ensure balanced distribution, regardless of the number of rows at the input and output.

We are capable of handling up to 400 products per minute per row.

Line Turner: It is sometimes necessary to turn all or part of the products for filling or for orientation in a package. We have developed a simple and highly effective system for turning products in line, with a throughput of up to 400 products per minute per row.

To learn more

Please do not hesitate to contact us for more information.

Our specialized teams will be happy to assist you and support you in your project.

APPLICATIONS

- Equipment for Biscuit Handling

- Classification of Dry Biscuits

- Biscuit Manufacturing Machines

- Systems for Turning Biscuit Rows Before Filling

- Processing and Handling of Biscuits Post-Production

- Biscuit Production Lines