Accumulator or in-line buffer

Description

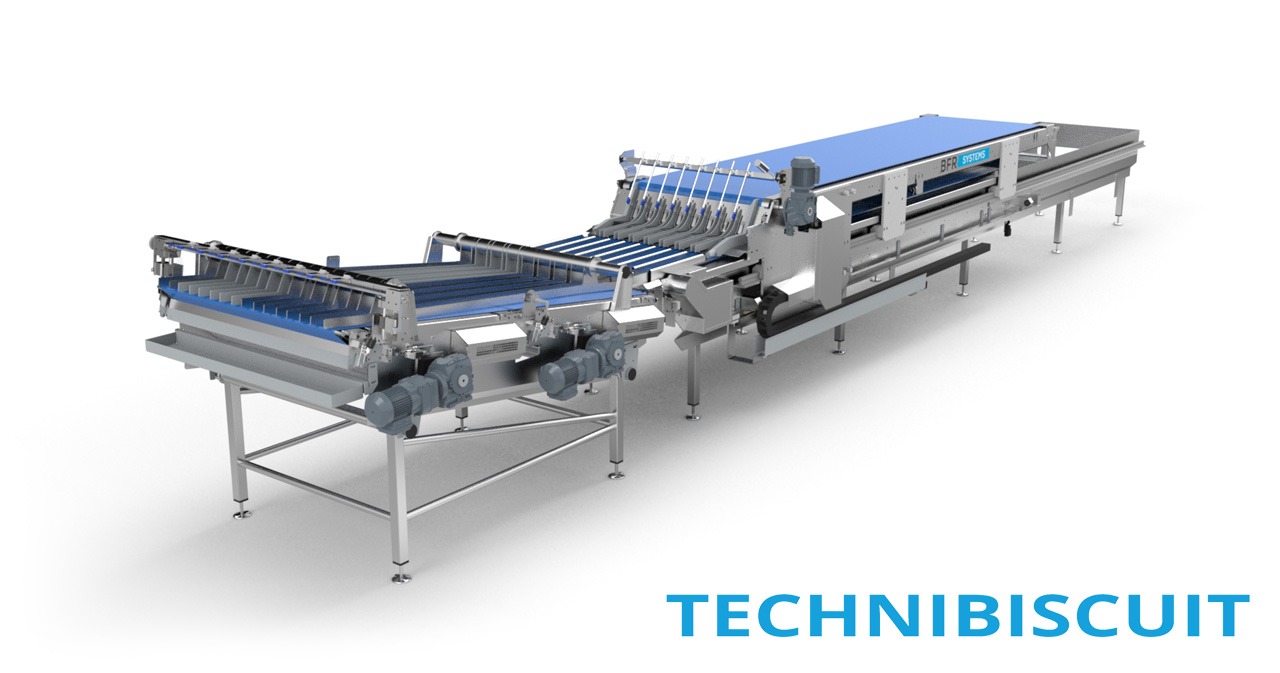

BFR SYSTEMS has developed several types of in-line accumulators for the biscuit, pastry, and viennoiserie industries.

In-line accumulators allow the product flow to be stored during a packaging stoppage and automatically reintroduced when it restarts.

There are two types of in-line accumulators: FIFO (First In / First Out) type accumulators and FILO (First In / Last Out) type accumulators.

In the biscuit industry, FIFO type in-line accumulators are commonly used:

The biscuits are placed on their edge by a rotating stacking bar (Penny stacker) or by stars and stored upright.

The accumulation length can be fixed and the fill rate of the in-line accumulator is then measured according to the inclination of the biscuits. The more inclined the biscuits are, the less the in-line accumulator is filled. The more vertical the biscuits are, the more the accumulator is filled.

The accumulation length can also be variable in which case it is called a mobile cart in-line accumulator. The mobile cart on which the biscuit edge placing devices are mounted can move over several tens of meters and thus offer a very large storage capacity for a reduced floor space.

In pastry and viennoiserie, we use flat in-line accumulators:

Flat in-line accumulators can be U-shaped (trombone buffer) or multi-level. If you would like information on this type of in-line accumulator, we invite you to visit the specific pages for these devices.

Features

Penny Stacker:

- With or without motorized rotating bar

- Possible placement between guides for automatic feeding of packaging machine

- Management of inclination and loading rate by multi-conveyor or vibrating channels depending on the case

Sar stacker:

- The in-line accumulator with biscuits placed on edge by a rotating star is available in full width or independent track versions

- In the independent track version, the in-line accumulator of biscuits placed on edge offers optimum storage quality and is commonly associated with a mobile cart for greater autonomy

- Cadence depending on the biscuits can go up to 400 biscuits per lane per minute.

- If the cart is mobile, its travel distance can be several tens of meters.

BFR SYSTEMS in-line accumulators are autonomous and have their own dedicated electrical cabinet.

BFR SYSTEMS in-line accumulators are designed to be easily cleanable, with simplified maintenance and fully automated operation.

APPLICATIONS

BFR SYSTEMS' line accumulators for upright biscuits are suitable for accumulating any type of dry biscuit, regardless of its shape.

Line accumulators can also be used with sandwich biscuits provided they are properly set at the time of stacking.