New Version of the Fixed Weight Cutting Machine ERMA EB80F: A Revolution in the Food Industry

BFR Systems presents the new version of its ultrasonic cutting machine, the ERMA EB80F. Specifically designed for cutting product bars into fixed-weight portions, this machine offers remarkable performance and a significant return on investment for our clients. Thanks to its precision, it limits the phenomenon of "give away," ensuring portions that comply with current regulations.

First developed in 2010, the initial version of the ERMA EB80F was very functional. The second version benefited from a more streamlined design and notable simplifications. This latest version further enhances cleanability and minimizes the risk of bacteriological contamination.

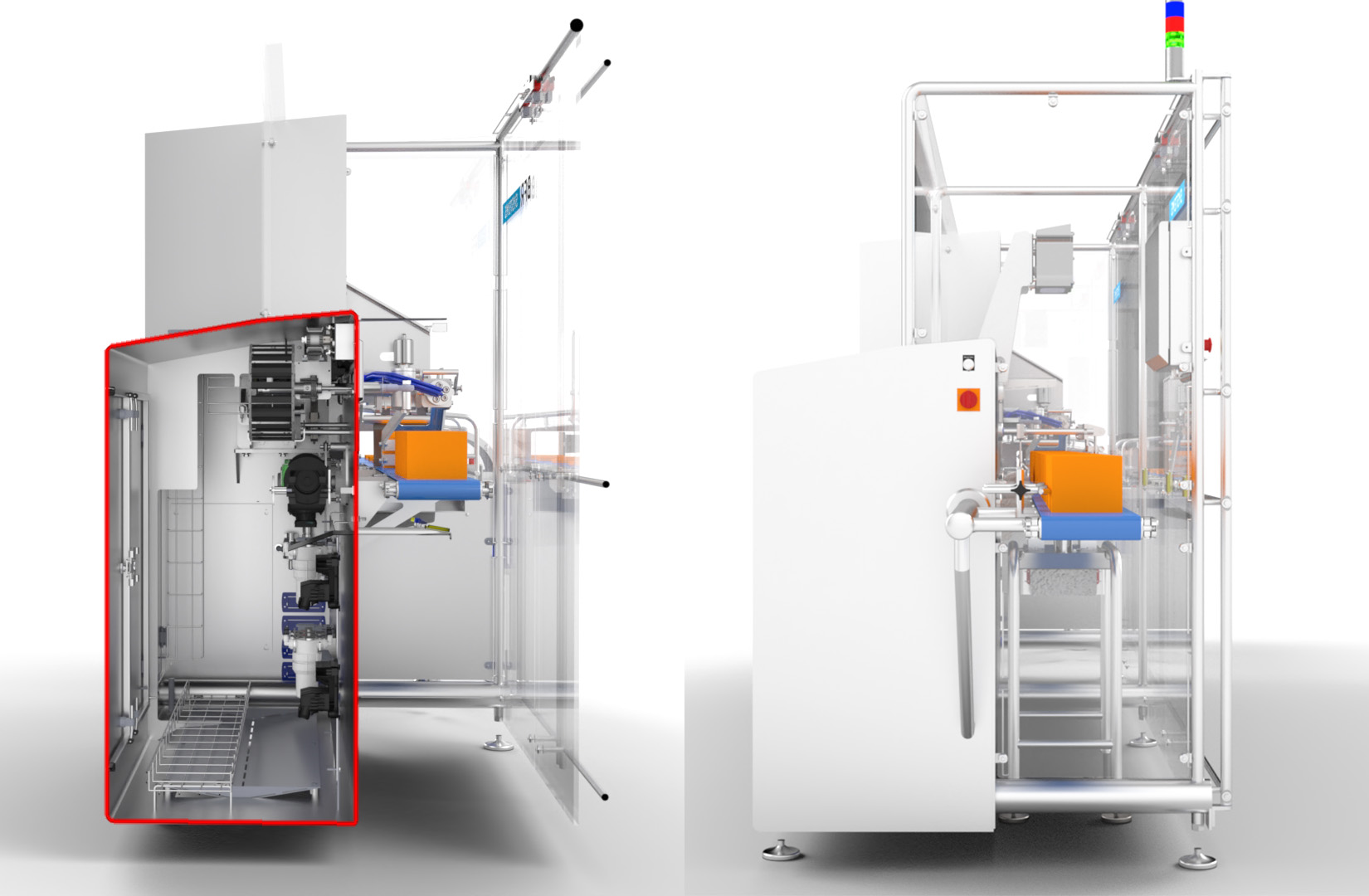

The ERMA EB80F machine stands out due to its advanced design, incorporating several essential components for precise and efficient cutting:

- Weighing Module: Integrated into the conveyor, it allows for the measurement of the weight of product bars.

- Centering Conveyor: Ensures optimal positioning of products for cutting.

- 3D Scanning System: Provides precise visualization of the external volume of products, without color constraints, including dark-colored products, thanks to a high-performance laser system.

- Ultrasonic Cutting Assembly: Developed by BFR Systems, made entirely of stainless steel and titanium, it withstands all cleaning products.

- The checkweigher: Functioning as a servo system, it provides continuous feedback by verifying weight conformity before packaging. For performance optimization, it continuously adjusts the target weight.

BFR Systems offers two variants of the ERMA EB80F machine to meet the specific needs of each client:

ERMA EB80F Classic: Equipped with an enhanced 3D camera for precise visualization without color constraints. ERMA EB80F RX: Equipped with an X-ray system to detect density variations in the material, ideal for holey cheeses like Emmental.

Operating Modes:

- Classic Fixed Weight: In this operating mode, portions are cut to the targeted weight, and a drop is created, corresponding to the cheese's excess weight insufficient for a complete portion.

- Distributed Fixed Weight: In this operating mode, the cheese is cut into an integer number of portions, and the excess weight is distributed among all the portions. Thus, the performance depends on the input cheese weight and its divisibility relative to the targeted weight. Hybrid Algorithm: Our machine also integrates a hybrid algorithm that automatically switches between the two operating modes based on the total weight of the product to be cut, ensuring maximum flexibility and precision.

The Anritsu checkweigher positioned after the cutting plays a crucial role in optimizing our cutting process. It is used in feedback mode to ensure that each portion reaches the target weight before packaging.

Key Features:

Continuous Control: The checkweigher continuously monitors the weight of outgoing portions. It automatically adjusts the cut to ensure each portion is as close as possible to the target weight. Advanced Algorithm: With our processing algorithm enriched by 23 years of experience, the checkweigher optimizes cutting precision in real-time.

Environmental and Financial Impact:

- Waste Reduction: By preventing non-compliant portions from reaching the packager, we reduce the need for unpacking and recycling, thus saving plastic film and limiting material loss.

- Improved Efficiency: Increased cutting precision minimizes the phenomenon of "give away" (overfilling), thereby enhancing yield and profitability.

Compatible Product Types:

The ERMA EB80F machine is versatile and can cut a wide range of products, including:

- Cheeses: Eurobloc, American blocks (40 lb and 640 lb), square wheels like Emmental

- Charcuterie

- Savory or sweet cakes

- Sticky, fatty products

Available Options:

To meet specific customer needs, several options can be integrated into the machine:

- Guillotine for cutting wheels into bars

- Transfer of waste to a single evacuation point

- Sizing of one or two sides of the loin

- Integration of a portion storage system for automatic loading of the packager

- Slice cutting

Design

Hygiene and Safety

Two essential and fundamental concepts on which BFR Systems relies to design and develop its products. All BFR Systems machines comply with current safety, hygiene, and cleaning standards.

Easy Disassembly and Maintenance

All our machines are equipped with quick and tool-free disassembly systems for the main components, facilitating cleaning and maintenance. The quick disassembly of the conveyor belts without tools ensures simplified and efficient maintenance and cleaning.

Easy Maintenance and Interventions

The kinematics of our machines are housed in a sealed enclosure, providing complete accessibility for maintenance. This design allows for quick and easy interventions, minimizing downtime.

Aesthetics and Ergonomics

We believe that the quality of the process cannot be separated from the quality of the machine. That’s why our equipment combines aesthetics and ergonomics, offering an optimal and pleasant user experience.

Stainless Steel Construction

Our machines are entirely constructed from stainless steel and protected by a sealed enclosure, ensuring the protection of sensitive components against splashes and high-pressure cleaning.

Modularity and Adaptability

Thanks to their modularity, our machines easily adapt to diverse production needs. They meet the strictest industry standards, offering flexible and customized solutions to our clients.

Conclusion

The ERMA EB80F offers a significant return on investment by limiting the phenomenon of "give away" (overfilling). The cut portions comply with current regulations, ensuring precise and efficient weight control. This precision reduces material waste, increasing the number of portions cut and packaged.

In summary, the ERMA EB80F machine from BFR Systems represents a strategic investment for any company looking to optimize its cutting processes, reduce material waste, and maximize profitability.