Conveyor Whistle

Description

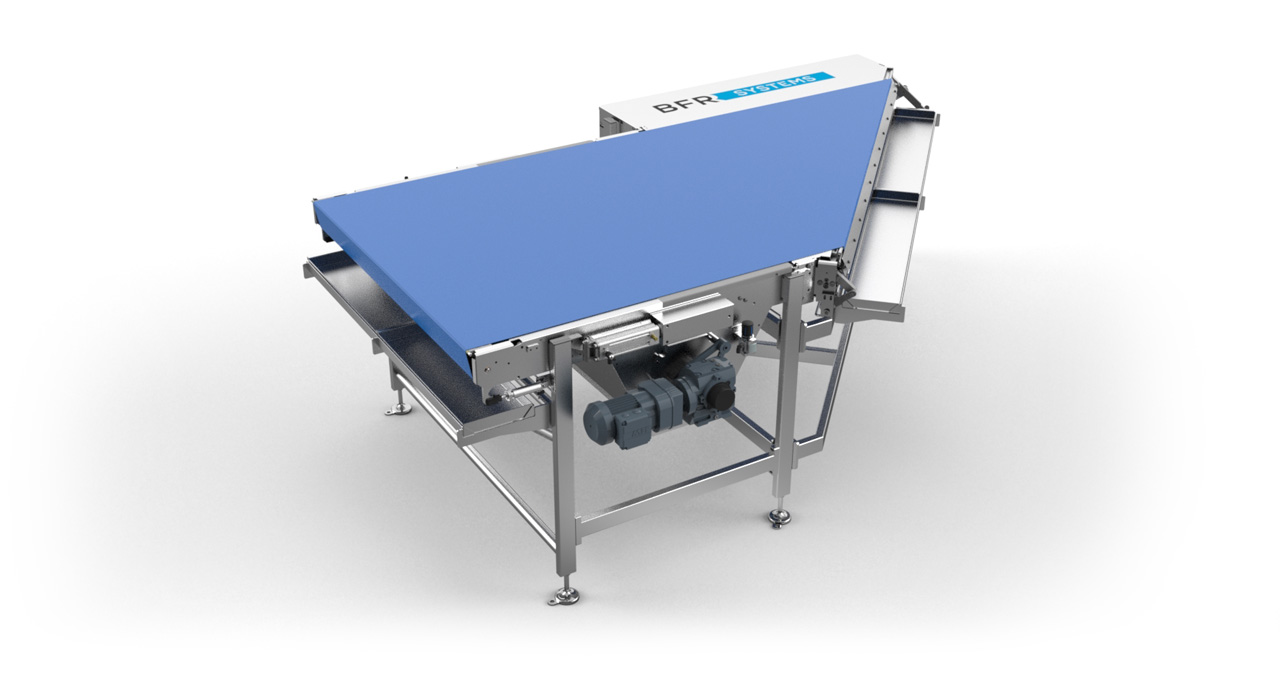

A sprocket-driven belt conveyor is a belt conveyor whose one end has a 45° angle on a fixed blade.

By combining a sprocket-driven belt conveyor with a straight conveyor, a curve or another sprocket-driven belt conveyor, it is possible to orient, separate, tighten, redirect at 90° or align products while minimizing contacts.

BFR sprocket-driven belt conveyors have the same characteristics as straight conveyors:

- Pneumatic belt tension

- Pneumatic belt tracking

- Small diameter ends for small products

- Continuous scraping with waste recovery tray

- Quick belt dismantling possible

- All-stainless steel design without retention zone allowing jet washing if necessary

APPLICATIONS

The applications of whistle conveyors are multiple:

- Widening the flow to facilitate the grip of products by robots, for example

- Narrowing the flow width to feed a tunnel, coater or any other equipment that is narrower than the original flow

- Combining a 90-degree product redirection with a contactless change of orientation

- Bringing back in line products that arrive ordered in rows

Whistle conveyors are commonly used in the biscuit-pastry, viennoiserie, chocolate, and snacking industries, whether in fresh or frozen products.

To learn more

BFR Systems, food packaging machine manufacturers and suppliers of production lines for the food industry. Expertise, innovation, and top-notch customer service.

Contact us today for tailor-made packaging solutions.