- FOOD & DAIRY

-

Equipments

Join us

Join our teams at the right time!

During your studies

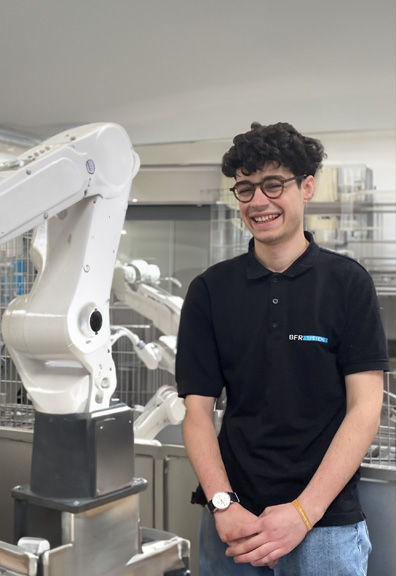

I joined the pre-project department as an apprentice 9 months ago. Graduated with a DUT in Mechanical Engineering and Production, I joined the Esiee engineering school.

The agri-food sector interests me a lot because it is constantly evolving and always offers business opportunities. Our consumption habits are certainly changing, but we will always continue to consume.

At BFR Systems, my role is to make an initial cost proposal for the customer, working closely with the sales team to understand their expectations and technical needs. We are the first link between sales and technical. We establish the feasibility of the commercial proposals by consulting the various design department (mechanical, electrical, automation, etc.). The goal is to create plans to propose coherent solutions technically and price-wise, while respecting safety and sanitary standards.

Here, I learn to innovate, to find existing techniques to create solutions never seen before. We regularly carry out technological monitoring and we constantly have to inform ourselves about the technical means already present. The more we have a broad knowledge of the market and its proposals, the more we can innovate and propose specific adaptations to each client.

What I like about what I undertake is that the days are not the same, the projects evolve and the customers' needs are constantly being renewed with the technological advances in the market. In addition, I get to collaborate with multiple areas, so I am constantly learning new things.

At the end of my three years of apprenticeship, my goal is to be able to make drawings and costings in complete autonomy and maybe to secure a permanent contract…

Baptiste