One of the most urgent challenges for the food industry is addressing growing concerns about the quality and safety of food products. Consumers demand safe and high-quality foods. To meet this requirement, we have defined a strict set of specifications and collaborated with our partners to design our new range of ultrasonic cutting technology.

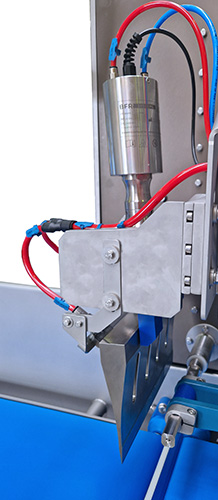

We now have an ultrasonic cutting system that is easy to clean and resistant to cleaning products. This technology offers great satisfaction in terms of cutting quality and ease of control.

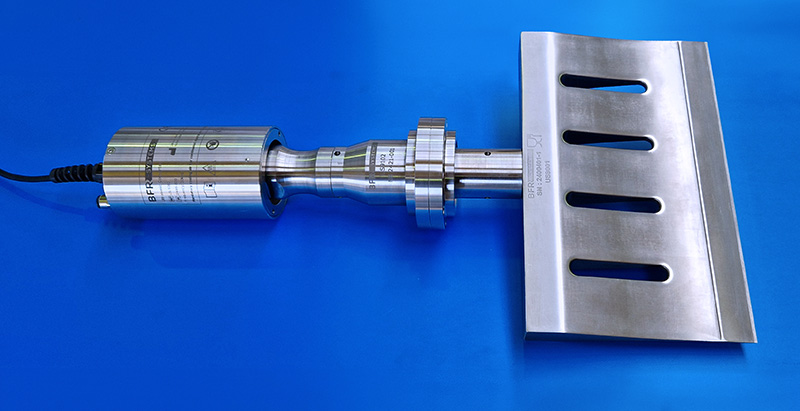

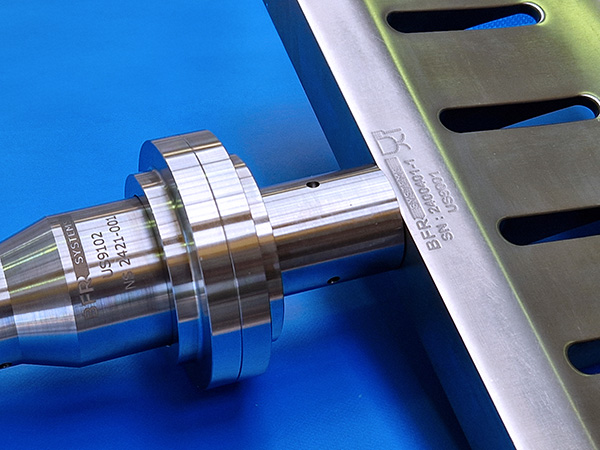

BFR Systems' new ultrasonic cutter is entirely made of stainless steel and titanium. Unlike some cutting assemblies that use aluminum parts, this design ensures increased durability and superior resistance to industrial cleaning products, thus minimizing bacterial risks. Rapid troubleshooting is crucial in the industry, which is why our new generator allows our technical services to connect remotely to diagnose and solve problems, providing efficient and quick technical support. We have also strengthened our supply chain to ensure the continuous availability of our products. Additionally, our after-sales service (SAV) can now respond more quickly to any request.

Ultrasonic Cutting: How It Works

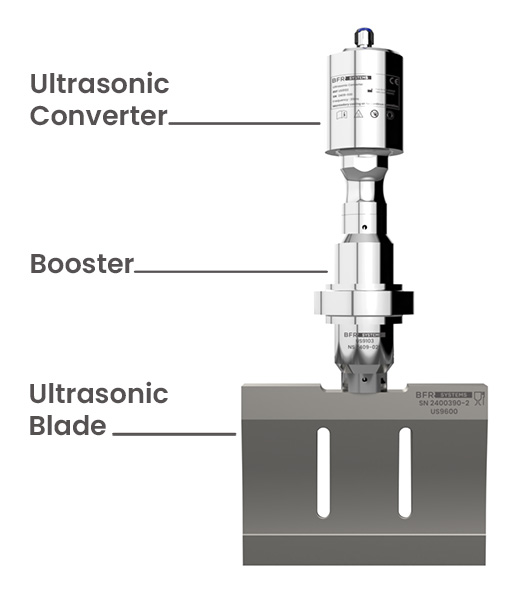

The principle relies on the vibration of a blade at high frequency, significantly enhancing the cutting power of the blade. An ultrasonic cutting assembly consists of the following components:

- Ultrasonic Generator: Converts the electrical network frequency (50/60Hz) into an ultrasonic frequency (20 kHz) and transmits this frequency via a high-voltage cable to the converter.

- Piezoelectric Converter: Transforms the electrical signal from the generator into high-frequency mechanical motion.

- Booster: Comparable to a gearbox, it adjusts the amplitude by reducing or increasing it.

- Ultrasonic Blade (Sonotrode): Made of titanium, it offers several advantages:

- Corrosion Resistance: Ideal for environments exposed to chemicals or moisture.

- Biocompatibility: Essential for food and medical industries, ensuring clean and contamination-free cutting.

- Acoustic Properties: Effectively transmits ultrasonic vibrations, ensuring precise cutting.

- Rigidity: Maintains precise cutting even under high load, minimizing deviations.

There are two lengths of ultrasonic blades: half-wavelength (14, 15 cm) and full-wavelength (25, 27 cm). This length is fixed because the wave must travel through the material and reach the other side at the right time. The amplitude must be at its maximum at the blade's tip.

Each blade length has several profiles, defined according to the type of product to be cut: pastries, cold cuts, cheese, etc. For example, there are seven different profiles for cheese applications.

Each blade length has several profiles, defined according to the type of product to be cut: pastries, cold cuts, cheese, etc. For example, there are seven different profiles for cheese applications.

With 23 years of experience in ultrasonic cutting, our experts are here to help you choose the best solution for cutting your products. If you have a project or want to learn more about ultrasonic cutting, our industrial site in Blyes, located in southeastern France, will be pleased to welcome you for cutting tests on your products and to showcase our machines.

In our showroom, you can perform cutting tests on your products and package them with our flow packs.