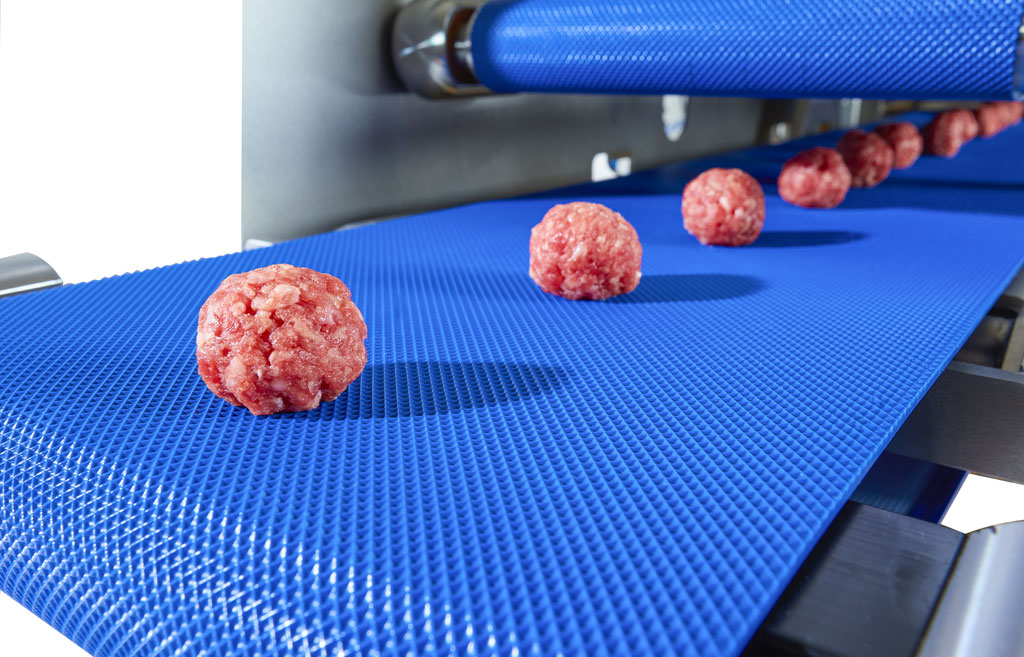

FM250 Forming Machine

Description

The forming machine allows molding of meat and vegetable-based deli products. Meat former, meatball former.

Usage

The forming machine is directly connected to VEMAG's continuous vacuum filler. An integrated chopping device ensures the last operation just before molding and chopping of the product. A calibrating belt gives the products advancing on the conveyor belt the desired final size. The separated products are then transferred to the next processing step.

Top-quality products

The products made with the forming machine stand out for their texture and natural structure when bitten into. As the forming machine processes the raw material gently, meat fibers are not compressed or destroyed, unlike typical production methods. The meat fibers of the finished product retain their original orientation, so that the finished product has the same structure when bitten into as a hand-made specialty. By integrating a chopping device with an optional automatic separation valve, hard components of the product such as bone fragments, tendons, or foreign bodies are properly separated from the product.

Its advantages at a glance

Recommended for a variety of products:

- Meatballs

- Ground beef patties

- Cevapcici

- Pork ribs

- Chicken nuggets

Easy modification of the product shape with adjustable molding nozzles

Very simple adjustment of the product size thanks to weight correction with the portioning computer

High product quality with good texture and a natural structure when eaten

High product safety thanks to the grinding and separation carried out during processing

Less reworked products = high utilization of the raw materials used

Less cleaning costs = lower costs

Flexible use

The forming machine is controlled by the portioning computer of the stuffer. The user can vary the size of the products by correcting the weights from the portioning computer. Adjustable forming nozzles allow for the production of products of various shapes (e.g. round, cylindrical, disc-shaped, as well as customized shapes).

Learn more about Vemag