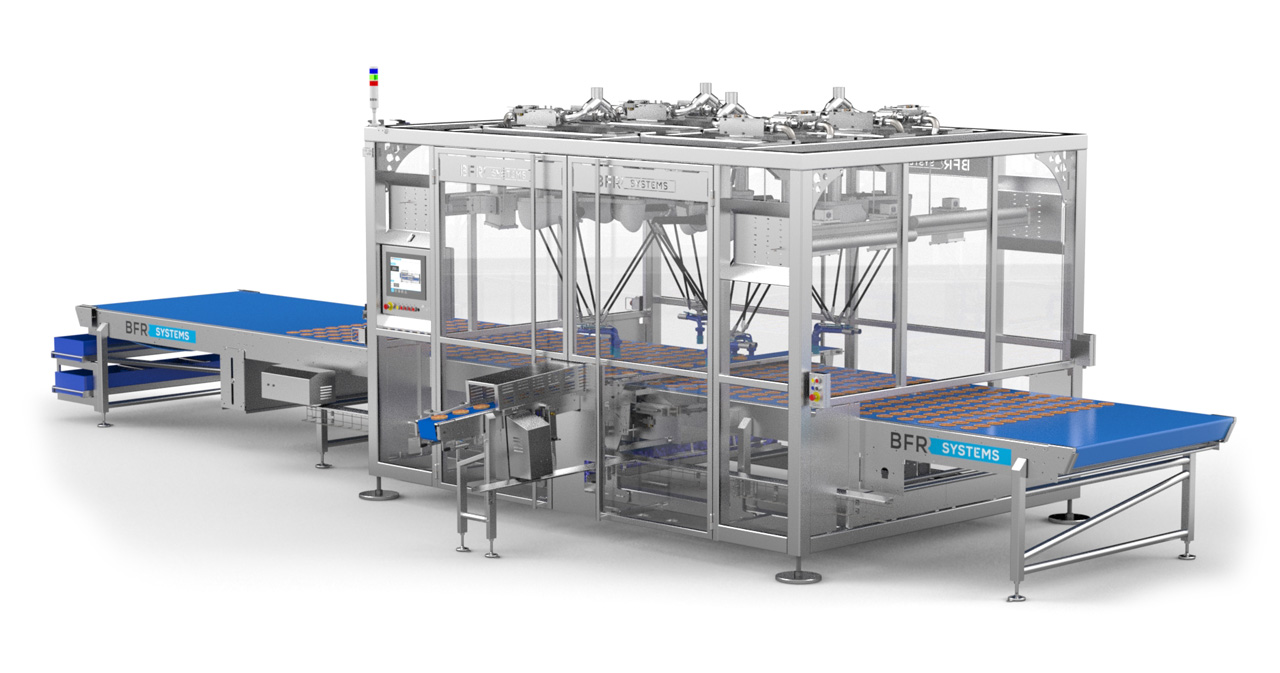

Robots station Pancakes packaging

Description

BFR SYSTEMS offers suitable solutions for the packaging of pancakes and large pancakes (crêpes).

Depending on whether the pancakes are baked on roundabout ovens (medium rates up to 12,000 products per hour) and arrive in unbalanced flow, or whether they are baked in tunnel ovens and are delivered in perfectly ordered rows (rate up to at 24,000 products per hour); Depending on whether they are fresh or frozen, BFR SYSTEMS has a solution for taking them back and packaging them.

Applications

The pancake is a fragile product and sensitive to bacteriological development. To preserve the pancakes, BFR SYSTEMS has developed grippers and high hygiene solutions that limit contact and friction.

The products are never touched laterally and all the parts that may come into contact with them (including the conveyor belts) can be dismantled quickly and without tools by the operators.

By integrating OMORI high speed orbital motion horizontal packaging machines, BFR SYSTEMS commits to a fully sealed filming solution and allows controlled and measured gas scavenging to preserve the shelf life of pancakes.

The multipack presentation can be horizontal or vertical, products stored or in bulk, depending on marketing choices.

Associated with OMORI (horizontal packaging machines) or UVA (vertical packaging machines), BFR SYSTEMS offers automatic and versatile solutions adapted to your needs.

Throughout the line, BFR SYSTEMS integrates measurement and safety equipment (metal particle detectors, checkweigher and X-ray inspection) by integrating the equipment of its partner ANRITSU.

Technical characteristics

- Speed up to 24,000 products per hour

- LIFO or FIFO buffer

- Multi-format wrapping individually or in stacks

- High hygiene design with full handling of the products (No friction of the products)

- Leakproof primary packaging in modified atmosphere