We are pleased to announce the launch of the fifth generation of our magnetic drive curved conveyor, the Euro-Magnet curved conveyor. Designed to meet the most stringent requirements of industrial environments, this innovative conveyor stands out for its robustness, versatility, and especially, the exceptional speed of its belt change, facilitating daily cleaning and maintenance.

Standard Stainless Steel Design

The magnetic curved conveyor features a standard stainless steel design, ensuring exceptional durability and increased corrosion resistance. Available in various useful belt widths (400, 600, 800, 1000, and 1200 mm), it adapts to a multitude of industrial applications. The inner radius is fixed at 180 mm regardless of the useful width. The ends, with a diameter of 20 mm, allow for smooth and continuous integration into existing production lines.

Optimal Performance and Safety

With a maximum speed of 45 m/min at the average radius on the smaller widths, the Euro-Magnet curved conveyor delivers top performance. It is capable of transporting loads up to 5 kg, thus ensuring high productivity without compromising safety or reliability. The design of the housing without play allows for optimal integration into any production line.

Easy and Quick Maintenance

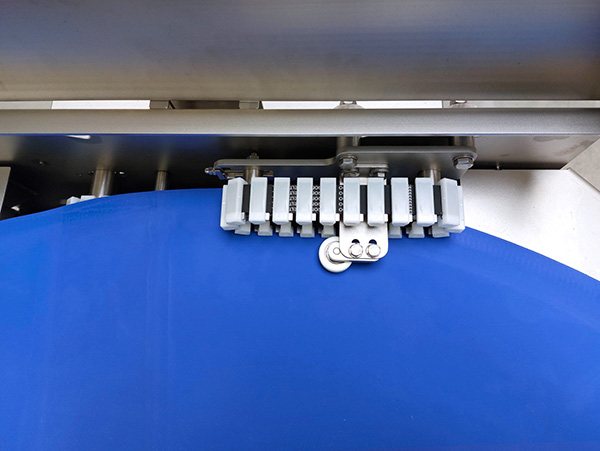

With several years of experience, we have optimized and improved the design of our Euro-Magnet curved conveyor. The belt is even easier to remove and replace. The highlight of this new conveyor lies in the speed of belt change, facilitating daily cleaning and maintenance. Thanks to the direct pinch drive of the belt between two tracks of magnets, the mechanical wear of parts is minimized. This ingenious system eliminates the need for bearings on end heads, rollers, elastics, or chains, significantly reducing maintenance needs.

Tool-less disassembly and automatic belt re-centering allow for quick and easy interventions. In just a few minutes, the belt can be changed, significantly reducing machine downtime and improving operational efficiency.

Adapted to Various Environments

The Euro-Magnet curved conveyor is designed to operate in various production environments, including those where the presence of grease, oil, or moisture is common, as well as in extreme temperature conditions typical of the food industry. Open frame structures and stainless steel frames allow for high-pressure maintenance without the formation of moisture pockets, minimizing bacteriological risks.

This grease-free mechanism is also a major asset, avoiding any risk of contamination by pollutants in the conveyance chain.

Ideal for Intensive Operation

Thanks to its advanced technical features, the Euro-Magnet curve is ideal for:

- Intensive operation with minimal wear

- Simplified and especially accelerated maintenance, thanks to the quick belt change

Available Options

To better meet the specific needs of each customer, several options are available:

- Stand on casters with brake for optimal mobility and stability

- Rotating ends Ø 14 mm for increased flexibility

- Electrical box with speed variator.

- Operation in both directions: clockwise and counterclockwise

In conclusion, the fifth generation of the magnetic drive curved conveyor represents a major advancement in the field of industrial handling. With its exceptional speed of belt change, facilitating cleaning and maintenance, it stands as an indispensable choice for any company looking to optimize its production processes while reducing costs and downtime.