PROCESS

With 60 years of experience in the process, BFR Systems is your partner to support you in your applications such as dosing, chopping, crushing, shaping, cooking, as well as mixing products.

We offer machines and equipment for the food industry, pet food, cleaning products, and pharmaceuticals. Our expertise in combining skills is a real asset that we have been cultivating for many years.

The group brings together the talents of several companies, each contributing its specific skills. Thanks to the combination of in-house production of standard or custom equipment and distribution, we can meet the needs of all companies, from the largest food industry players to the smallest SMEs. Trust our expertise to improve your productivity and efficiency.

CUTTING

BFR Systems has expertise in several technologies, including ultrasound which offers better cut quality and greater precision. We offer ultrasonic cutting machines for slicing, exact or variable weight portioning, cubing, using either ultrasonic cutting or conventional blades.

With 40 years of experience in cutting solution, our specialized team advises you on the possibilities of cutting. Working closely with you, we offer solutions that meet your needs. Our expertise in combining skills is a real asset that we have cultivated for many years. The group brings together the historical experience of several companies, each contributing their specific skills. Through the combination of in-house production of standard or custom equipment and distribution, we can meet the needs of all types of companies, from SMEs to the largest actors in the food industry.

CONVEYOR

With 60 years of experience in material handling systems, BFR Systems is your partner to support you in applications such as transport, delivery, automated handling, and logistics flow optimization. We offer a complete range of conveyors, conveyor systems, and transport equipment for industries such as food processing, logistics, distribution, and pharmaceuticals.

Our expertise in flow management and conveyor technology integration has been a true asset for many years. The group brings together the talents of several companies, each contributing its specific skills in the field of transport and material handling systems.

Thanks to the combination of in-house production of standard or custom equipment and the distribution of high-performance solutions, we can meet the needs of all companies, from large industrial groups to the smallest SMEs. Trust our expertise to improve your productivity, optimize your production flows, and maximize your efficiency.

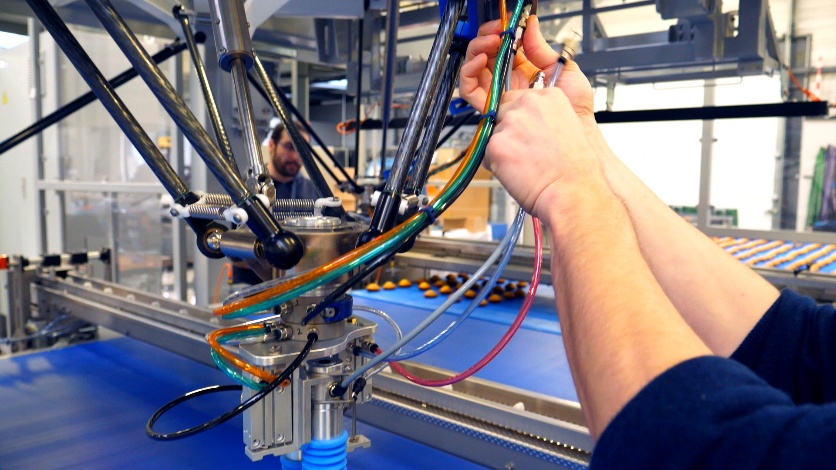

HANDLING

We provide machines for handling your products, whether they are naked or packaged. These machines include accumulators, groupers, stockers, robots, conveyors, and stackers. We also offer automatic loading solutions for packaging machines, feeding a cutting station, ...

With 60 years of experience in handling food, our robotics and automation specialists offer customized solutions tailored to your specific needs.

Our expertise in combining skills is a real asset that we have been cultivating for many years. The group brings together the talents of several companies, each contributing its specific skills. Thanks to the combination of in-house production of standard or custom equipment and distribution, we can meet the needs of all companies, from the largest food industry players to the smallest SMEs.

Trust our expertise to improve your productivity and efficiency.

PACKAGING

We offer a wide selection of packaging and automatic loading solutions to meet all your needs, such as film packaging, vertical bagging, or cartoning. At BFR Systems, we are committed to providing you with the appropriate solution for your packaging needs. We offer a variety of packaging solutions such as flexible bags, pillow bags, stand-up packs, peelable seal bags, and overwrapping, whether in manual or automatic stations. We also offer printing and marking options such as inkjet or thermal transfer printing or gas flush packaging. At BFR Systems, we are proud to be a machine manufacturer that uses eco-friendly packaging. The versatility of our machines allows us to adapt to the latest trends in eco-friendly packaging, meeting the needs of our customers while fulfilling our commitment to the environment.

CONTROL

As experts in measurement and control, we provide solutions to ensure the quality of your production. We offer visual inspections by camera, X-ray or metal detectors to ensure material compliance. We also provide weight control solutions using checkweigher to guarantee dosage accuracy. Finally, we offer weld quality inspections to ensure the strength and durability of your products. In short, our expertise allows you to confidently guarantee the quality of your production. We guarantee the highest level of safety and quality by combining our production line solutions with those of expert partners in measurement and control. Quality control technologies such as metal detection, dynamic weighing, camera inspection, and infrared detection all ensure the quality of industrial products by detecting defects and eliminating defective products from production.