Lassoudry

LASSOUDRY WAS FOUNDED IN 1959 AND HAS BEEN PART OF BFR SYSTEMS SINCE 2019.

The company quickly met with success due to the quality its process machinery and its customer service. Our experience allows us to offer innovative equipments that meet the requirements of our clients.

Why Lassoudry ?

- • The best solutions adapted to your needs.

- • High quality equipment.

- • Innovative solutions.

- • Fast and efficient after-sales service.

COMPLETE PREPARATION LINE

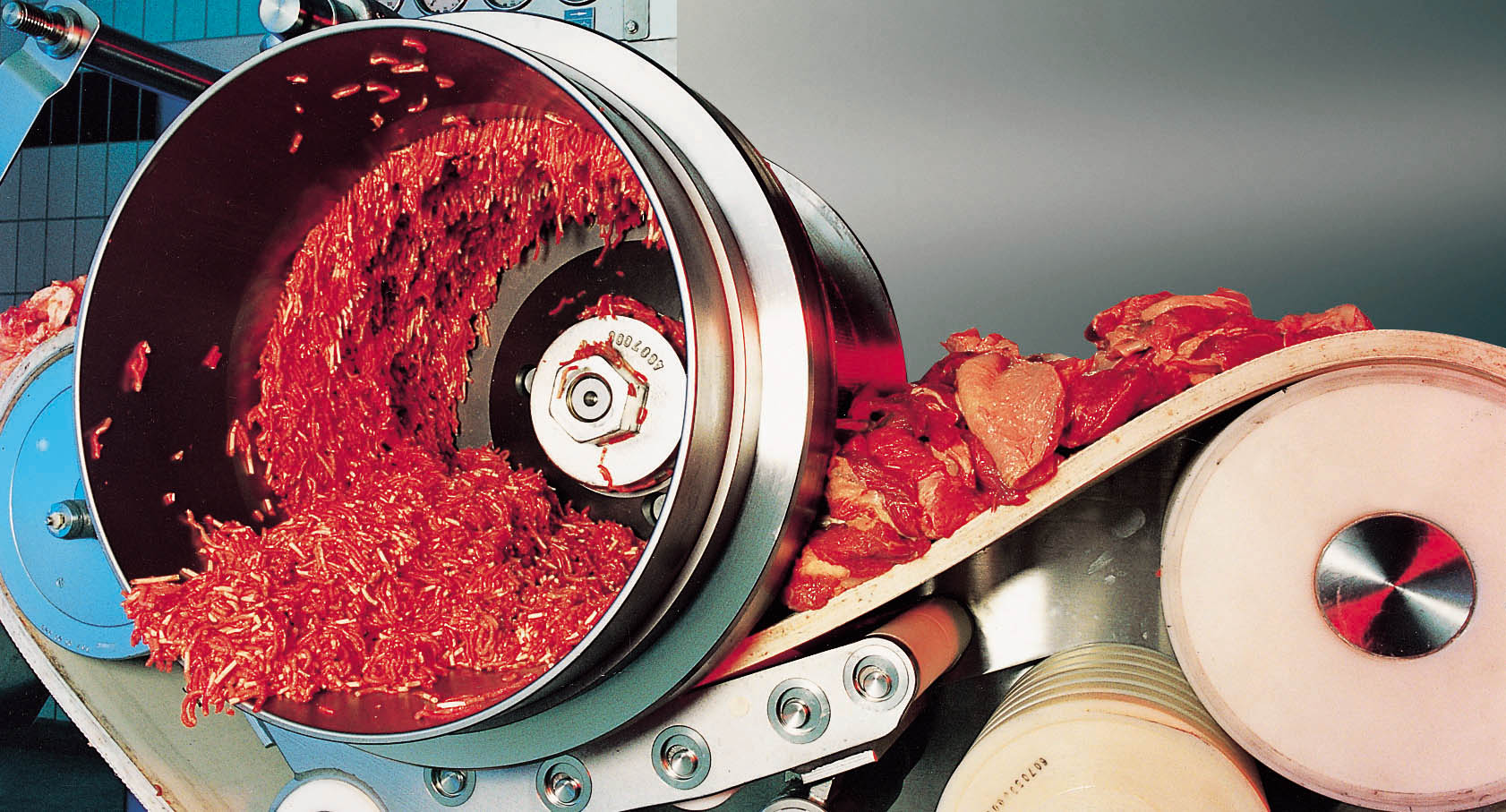

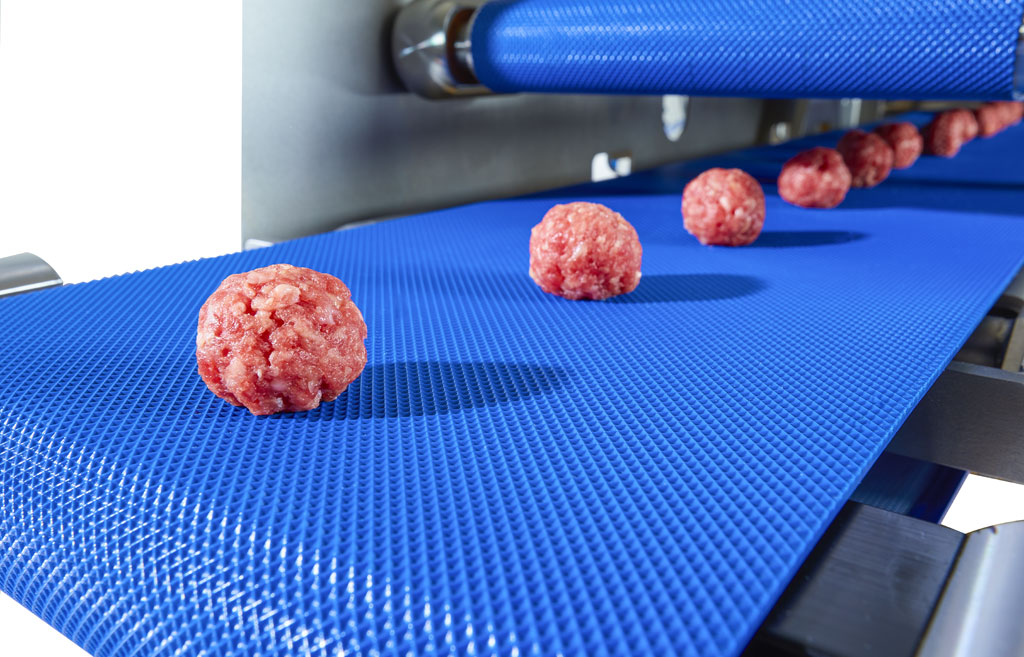

Minced meat line .

- The product arrives via elevator and inclined belt

- Mincing of fresh and frozen meat

- Transfer with screw or belt

- Mixing and cooling (possible cryogenics)

- Meat standardisation

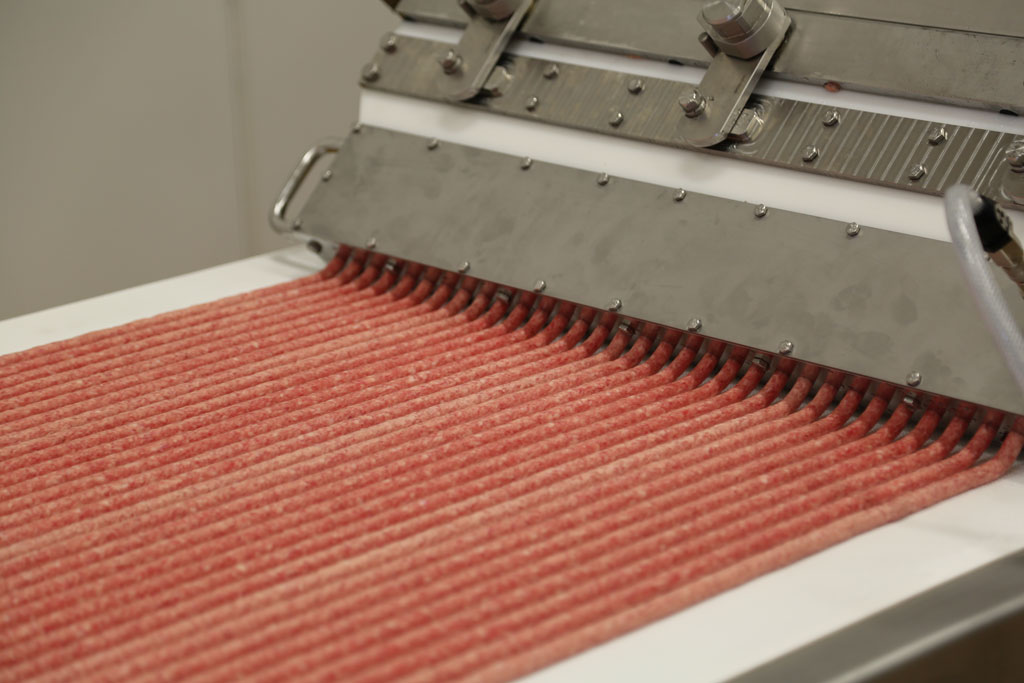

- Complete line for product of minced meat, saussage, topping,...

- Cooking and cooling of minced meat

SCANSTEEL MIXERS

Our mixers enable efficient mix, respecting the products thanks to interpenetration of the blades. The speed can be fixed (depending on the application) or variable for optimal polyvalence. If needed the mixer can be equipped with CO2 or azote injection. Once mixed, product will pass trough an emptying trap or a mincer.

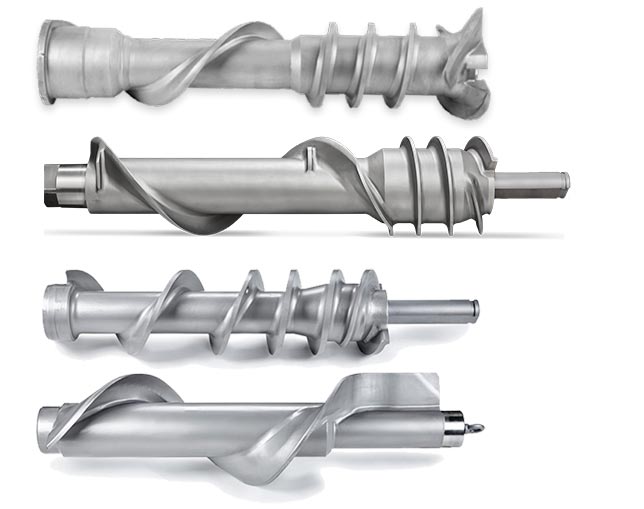

VEMAG STUFFER

VEMAG H.P.E stuffer uses double-screw technology which guaranty:

adaptability, respect of the product, dosage precision. Maintenance is easy thanks to a limited number of moving pieces, and easy disassembly.

Graphic driving panel enables an easy and intuitive control of the pusher and all VEMAG accessories: HPE is then the best base to produce logs of goat cheese or to dose, form, extrude a wide range of food products.

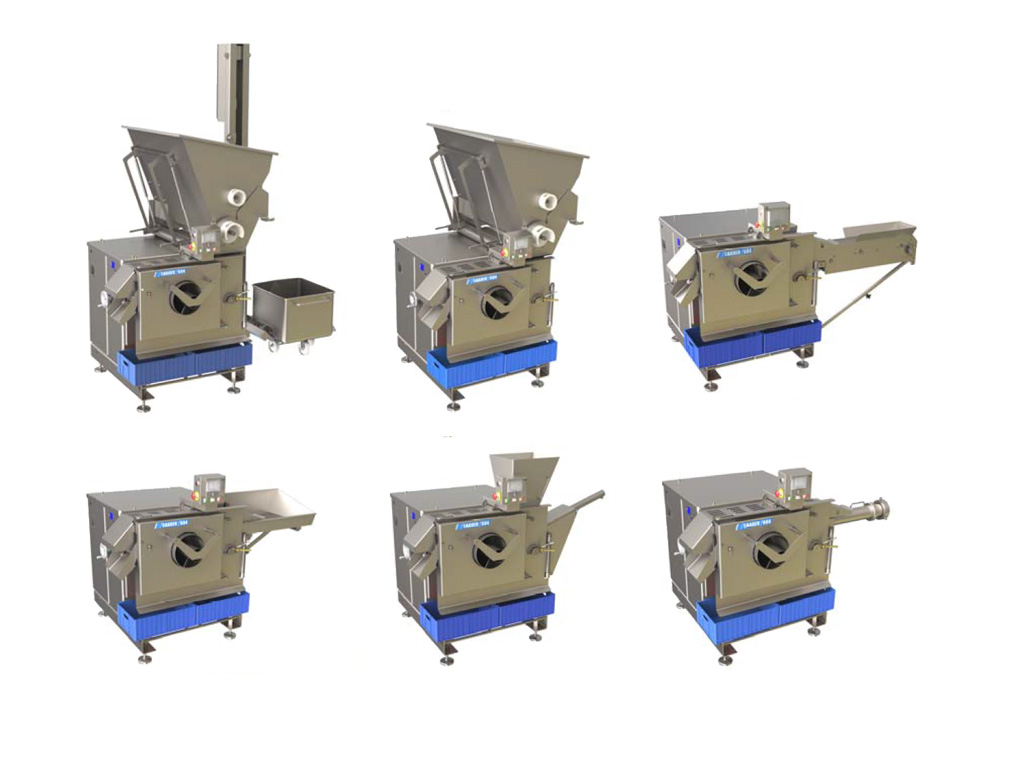

BAADER SEPARATOR

BAADER has developed a unique and worldwide proven method for separating soft and solid components for a wide range of applications:

- Desinewing from pre-cut red meat, poultry and fish

- Puree and juice production from fruits and vegetables

- Depackaging of small packages

A variety of raw product can be refined using this method.

A squeezing belt feeds the product to a perforated drum and presses the soft components through the holes of the drum. The solid components remain outside the drum. The ratio between yield and quality can be influenced by means of adjusting the pressure roller.